Hydraulic System for CNC Lathe

Optimizing CNC Machine Hydraulic Systems for Enhanced Efficiency

CNC machine hydraulic power packs utilize pressurized fluids to perform critical functions such as securely clamping workpieces via chucks and tailstocks, enabling rapid and precise turret tool changes, and providing reliable spindle braking. These integrated hydraulic operations enhance machining precision, operational efficiency, and overall safety.

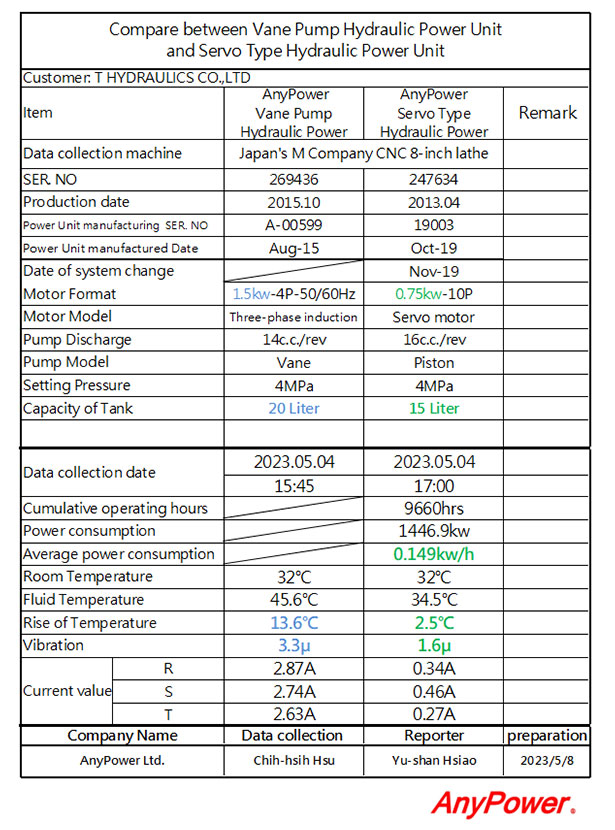

Challenges of Traditional Hydraulic Systems in CNC Machine

- Hydraulic Pump Idling for Long Periods:

In CNC lathes, chucks and tailstocks do not require continuous hydraulic supply during machining. However, traditional hydraulic systems keep the pump running continuously, leading to unnecessary energy consumption. - Low Pressure Demand but High Sensitivity to Pressure Fluctuations:

During workholding and turret tool changing, a high-pressure surge is required instantly. Traditional hydraulic units struggle to respond quickly, causing pressure drops that negatively impact machining accuracy. - Overheating Issues:

Continuous operation of traditional hydraulic systems generates excessive heat, degrading the performance and stability of hydraulic oil, which affects machining precision.

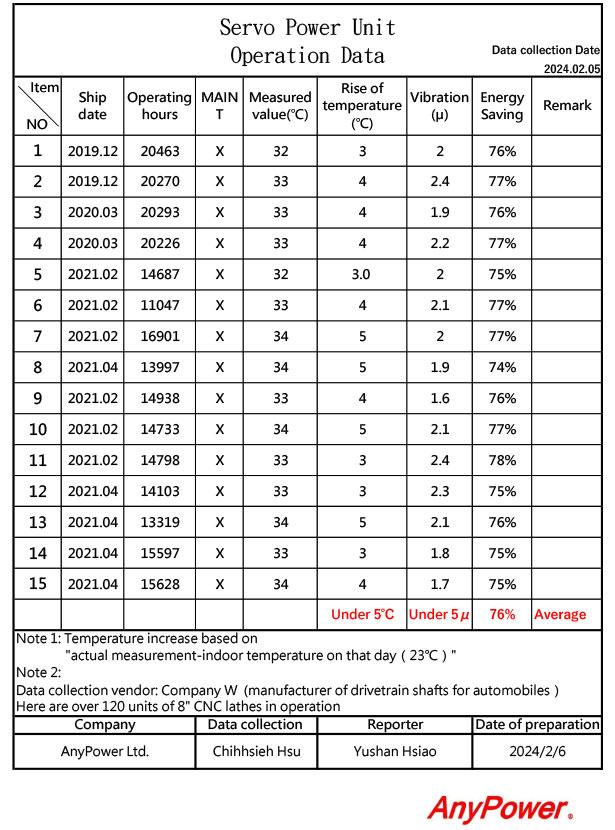

Benefits of Switching to ANYPOWER Servo Hydraulic System:

- Pressure is supplied only when needed, eliminating unnecessary energy consumption during pressure holding.

- Fast response time (0.01s), minimizing pressure drops and improving machining accuracy.

- Prevents overheating from continuous operation, reducing the impact of high temperatures on machining precision and hydraulic oil stability.

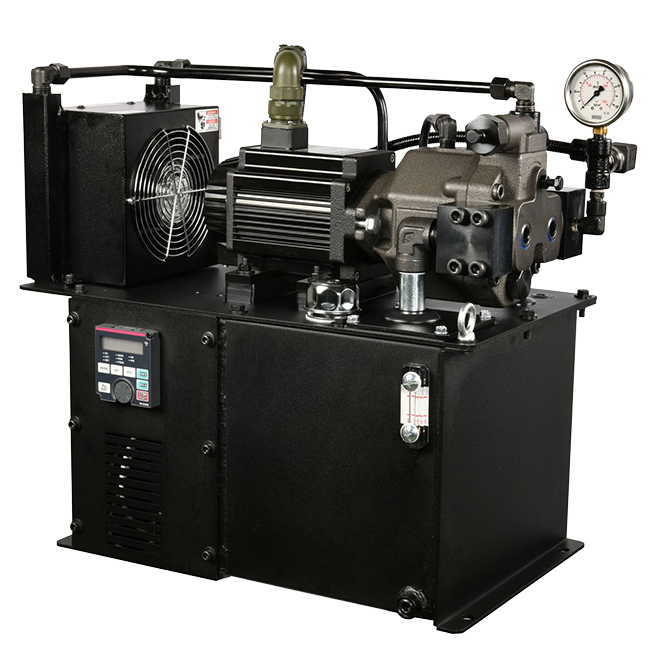

AnyPower Servo Power Unit

AnyPower Servo Power Unit